Manufacturing PDMS slabs in just 3 minutes and reducing chip costs to a fraction of manual casting

Request a QuoteFounded by engineering teams from the University of Michigan and the University of Wisconsin, ProtoDive combines expertise in precision manufacturing with advanced semiconductor process technologies. Built on over a decade of microfluidic research, we deliver end-to-end solutions—from design optimization to scalable, high-volume production.

No more production constraint when considering PDMS as your solution. Our industrial-grade injection molding technology offers substantial advantages over traditional lab-molded PDMS devices.

Our proprietary injection molding system produces PDMS chips in just 3 minutes per unit, compared to hours with traditional methods.

Industrial precision ensures identical chips every time with precise channel dimensions and perfect surface properties.

Automated manufacturing brings chip costs down to single digits, making microfluidics accessible for large-scale applications.

From prototyping to high-volume production with the same tooling, supporting your growth from lab to market.

Our technology enables intricate channel designs, multi-layer structures, and integrated components not possible with soft lithography.

Seamless transition from research prototypes to commercial manufacturing with validated processes.

The ProtoDive injection molding advantage delivers superior microfluidic devices with unprecedented speed and precision.

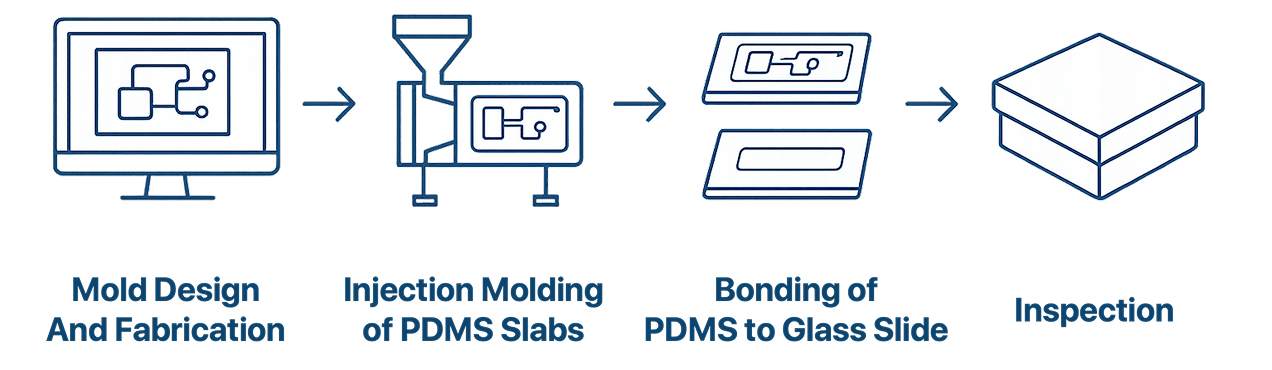

Traditional PDMS chip fabrication relies on manual soft lithography processes that are time-consuming, labor-intensive, and difficult to scale. Our proprietary injection molding technology transforms this process:

Computer-controlled injection systems deliver exact amounts of PDMS with consistent mixing ratios.

Advanced thermal control systems cure PDMS in minutes rather than hours.

Specialized mold coatings and release mechanisms eliminate manual demolding steps.

In-line optical inspection ensures every chip meets exact specifications.

Options for embedded components, stiffness gradients, and functional surface modifications.

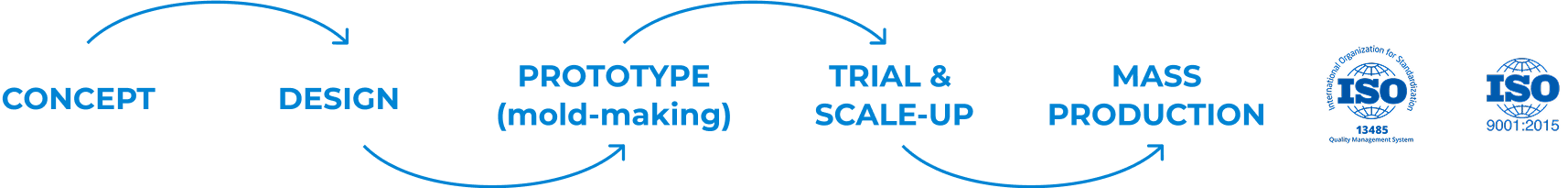

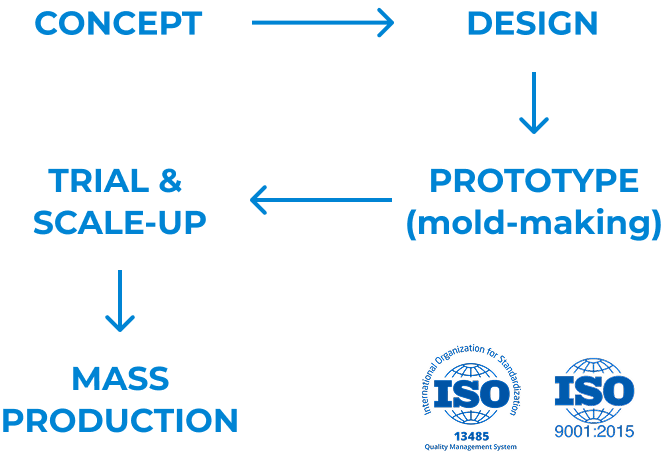

From design optimization to full-scale production, we support your microfluidic chip needs at every stage.

Our microfluidics experts will review your designs and suggest optimizations for manufacturability while preserving functionality. We provide guidance on channel dimensions, aspect ratios, and surface treatments to ensure your design is production-ready.

Fast turnaround from CAD files to functional prototypes, allowing iterative improvements and validation testing. We can deliver test chips within days of design approval, accelerating your development cycle.

Flexible manufacturing of small quantities (20-1,000 units) for pilot studies, clinical trials, or market testing. Our tooling approach makes small batches economically viable without compromising quality.

Scalable production capacity for commercial applications (10,000+ units) with consistent quality and competitive pricing. Our automated production lines ensure reliable supply for your growing demands.

We work on the most challenging designs and deliver the most consistent PDMS chips.

100 µm micropillar array of 3D tumor micro-environment required for cell encapsulation and perfusion

Through-PDMS conduits to reduce dead volume of costly anticancer drugs

Dual-sided channel design with built-in connectors

Extreme thin wall (0.1mm) bottom design for the best cell observation experience

Strict thickness uniformity requirement for PDMS production

High bonding strength to provide leak-proof and pressure resistance

Micron-scale precision tolerance to ensure reliable and consistent separation

Contaminant-free channels to prevent clogging for smooth operation

Tell us about your project and our team will provide a detailed quote and consultation. Or send your request directly to info@protodive-microsystems.com We will contact you asap.